In the lush, tropical landscapes of Southern India, a quiet revolution is taking place. Local innovators are transforming banana leaves—once considered agricultural waste—into a sustainable, biodegradable alternative to plastic packaging. This eco-friendly solution is not only addressing the global plastic pollution crisis but also empowering farmers, supporting local economies, and reviving a traditional practice with modern innovation. Let’s dive into how banana leaves are reshaping the packaging industry and why this movement is a game-changer for sustainability.

- Cell Structure: Made – Primarily of cellulose, Hemicellulose, and lignin.

- Waxy Cuticle: Hydrophobic wax layer – make it naturally water resistance.

- Antimicrobial Properties: Contain polyphenols & secondary metabolites – with antimicrobial activity- prevent food from contamination while preserving.

The Plastic Problem: Why We Need Alternatives

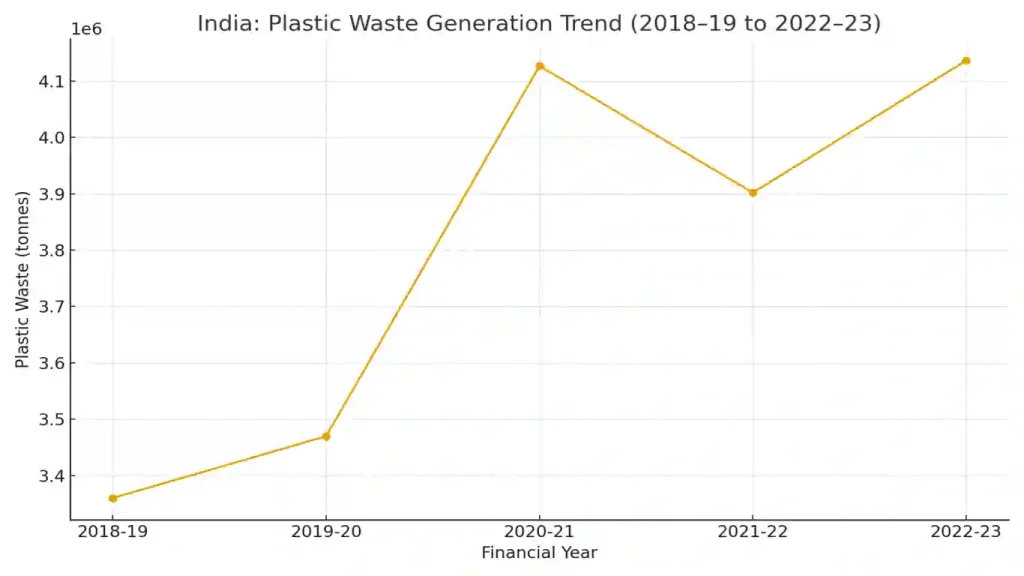

Plastic pollution is a global crisis. According to the United Nations Environment Programme, over 5 trillion single-use plastic bags are used worldwide each year, clogging landfills, polluting waterways, and harming marine life. In India alone, the Central Pollution Control Board reported that 62 million tons of waste were generated in 2015, with plastics forming a significant portion. Single-use plastics, like food packaging, take centuries to decompose, releasing harmful chemicals into the environment.

Southern India, with its rich agricultural heritage, is stepping up to combat this issue. Banana leaves, a byproduct of banana cultivation, are abundant, renewable, and 100% biodegradable. By turning waste into wealth, innovators are creating a circular economy that benefits both the environment and local communities.

Also Read: Ocean carbon: Evolutionary impact On Marine Life

Banana Leaves: A Natural Packaging Powerhouse

Banana leaves have been a part of Indian culture for centuries, used traditionally to serve food during festivals, weddings, and daily meals. Their natural properties make them ideal for packaging: they’re waterproof, flexible, and have natural antibacterial qualities that help preserve food. In just 28 days, banana leaves decompose naturally and safely, unlike plastic which lingers and pollutes.

| Property | Banana Leafs | Plastic Packaging | Paper Packaging |

| Biodegradability | 2-4 weeks | 500-1000 years | 2-5 months |

| Chemical Leaching | None | BPA, phthalates | Minimal (if untreated) |

| Water Resistance | Naturally water – repellent | High | Low (unless coated) |

| Production Impact | Low (agricultural byproduct) | High (petroleum-based) | Moderate (tree felling, energy use) |

What makes this innovation unique is the modern twist. Startups and inventors in Southern India are enhancing banana leaves using chemical-free, cellular technology to extend their shelf life and durability (contain polyphenols and secondary metabolites). For instance, Tenith Adithyaa, a young innovator, developed Banana Leaf Technology in 2010, which preserves leaves for up to one year with their natural green color and up to three years without it. This process strengthens the leaves’ cell walls, making them resistant to extreme temperatures and capable of holding more weight than raw leaves.

Current Scientific innovations

- Preservation Techniques: Research is ongoing to increase shelf life of banana leaves by coating them with natural resins or freeze-drying, preventing wilting for long-distance transport.

- Hybrid Packaging: Scientists are experimenting with combining banana leaves and biopolymers (like polylactic acid) for advanced biodegradable containers.

- Microbial Resistance Studies: Studies confirm banana leaf extracts show inhibition against bacteria such as E. coli and Staphylococcus aureus, making them even more promising for food safety.

Startups Leading the Charge

Southern India has become a hub for startups creating eco-friendly packaging from banana leaves. Here are a few trailblazers:

- Taruwar Agro (Bihar): Since its founding in 2021 by Jagat Kalyan, Satyam Kumar, and Nitish Verma, the startup has been redefining sustainability by turning banana fiber, leaves, and pulp into practical products like folders, yoga mats, and packaging alternatives. By processing 600 kg of banana waste every month and achieving ₹50 lakh in annual turnover, they are building a sustainable market in states like Kerala, Tamil Nadu, and Gujarat.

- Banana Leaf Technology Products: Pioneered by Tenith Adithyaa, this company produces durable, biodegradable packaging like plates, cups, and boxes. Their products align with 10 of the 17 UN Sustainable Development Goals, offering a chemical-free, animal-fodder-friendly alternative to plastic.

- INTUGREEN (Coimbatore, Tamil Nadu): Specializing in biodegradable tableware, this startup uses banana leaves alongside other natural materials like areca leaves and bagasse to create eco-friendly dinnerware for restaurants and catering services.

These startups are not just creating products; they’re building a movement. By sourcing leaves from local farmers, they provide additional income streams, turning agricultural waste into a valuable resource.

Empowering Rural Communities

What sets Southern India’s banana leaf packaging revolution apart is its deep connection to rural communities. Though India produces 14.2 million tonnes of bananas annually—the highest in the world—close to 60% of the biomass, from leaves to stems, remains unutilized and wasted. Startups like Taruwar Agro are changing this narrative by upcycling every part of the banana plant, creating a zero-waste model that empowers farmers.

For example, farmers in Bihar and Tamil Nadu, who once burned or dumped banana leaves, now sell them to startups, earning extra income. This not only reduces waste but also supports rural economies, aligning with India’s Swachh Bharat (Clean India) mission and global sustainability goals. The cultural significance of banana leaves adds an emotional resonance, making this innovation a blend of tradition and modernity.

The Science Behind Banana Leaf Packaging

The innovation lies in enhancing the natural properties of banana leaves. Traditional leaves deteriorate quickly, limiting their use. Modern techniques, like those developed by Banana Leaf Technology, involve cellular enhancement to strengthen cell walls (cellulose, hemicellulose, and lignin), prevent microbial degradation (polyphenols and secondary metabolites), and naturally water-resistance. The process is entirely chemical-free, ensuring the leaves remain safe for food contact and biodegradable.

Microwave-assisted drying, as studied in Indonesia, is another method being explored to optimize leaf preservation while minimizing energy use. These advancements make banana leaves a viable alternative to plastic, capable of being molded into plates, bowls, cups, and even exportable packaging materials.

| Year | Market Size (USD billion) | CAGR (%) |

| 2023 | 2.06 | – |

| 2024 | 2.18 | 6.0 |

| 2025 | 2.31 | 6.0 |

| 2030 | 2.38 | 6.0 |

This chart highlights the rapid growth of India’s biodegradable packaging market, driven by consumer demand and government policies like the Plastic Waste Management Rules.

Benefits of Banana Leaf Packaging

- Eco-Friendly: Banana leaves are 100% biodegradable, decomposing naturally within 7-10 days without harming the environment.

- Cost-Effective: Leaves are a byproduct of banana cultivation, making them inexpensive compared to plastic (Rs 5 per meter vs. Rs 40–60 for plastic or aluminum foil).

- Cultural Appeal: Their vibrant green color and cultural significance make them visually appealing and nostalgic.

- Health-Safe: Unlike synthetic packaging, banana leaves contain no harmful chemicals like bisphenols (BPA), and phthalates ensuring healthier food storage.

- Versatile: From plates to wrappers, leaves can be molded into various shapes for diverse applications.

| Year | Banana Production (Million Tonnes) | Biomass Waste (%) |

| 2020 | 14.2 | 60 |

| 2021 | 14.5 | 58 |

| 2022 | 14.8 | 57 |

| 2023 | 15.0 | 56 |

This chart shows the massive potential for upcycling banana waste, with startups reducing waste percentages through innovative packaging solutions.

Challenges and Opportunities

Despite its promise, the banana leaf packaging industry faces challenges. High initial costs for processing technology and limited supply chains for biodegradable materials can hinder scalability. Additionally, consumer awareness about sustainable packaging is still growing, requiring education and marketing efforts.

However, opportunities abound. Government initiatives like Startup India and MSME schemes offer tax exemptions, funding, and regulatory support for green startups. The Plastic Waste Management Rules and Extended Producer Responsibility (EPR) mandates further encourage businesses to adopt sustainable alternatives. With Southern India’s urban centers like Bangalore and Hyderabad leading in food delivery, the demand for biodegradable packaging is skyrocketing.

How to Start Your Own Banana Leaf Packaging Venture

For entrepreneurs looking to enter this space, here are key steps:

- Research and Feasibility: Conduct a feasibility study to understand local banana leaf availability and market demand.

- Technology Investment: Partner with innovators like Banana Leaf Technology for preservation techniques or invest in microwave-assisted drying systems.

- Compliance: Obtain necessary licenses, including pollution control and EPR registration.

- Supply Chain: Build relationships with local farmers and suppliers for a steady leaf supply.

- Marketing: Highlight the eco-friendly and cultural benefits to attract eco-conscious consumers and businesses.

Platforms like Solution Buggy can provide end-to-end consulting for setting up such ventures, connecting you with suppliers and experts.

Conclusion

The rise of banana leaf packaging in Southern India is more than a trend—it’s a sustainable revolution rooted in tradition and innovation. By transforming agricultural waste into eco-friendly products, startups are tackling plastic pollution, empowering farmers, and preserving cultural heritage. With a growing market, supportive policies, and increasing consumer awareness, banana leaf packaging is poised to reshape the future of sustainable packaging. As Southern India leads the way, this movement offers a blueprint for the world: sustainability starts with nature’s gifts and human ingenuity.

FAQs

Are banana leaves eco-friendly?

Yes, banana leaves are eco-friendly. They are biodegradable, sustainable, and often used as a natural alternative to plastic for wrapping food.

How long will banana leaves last?

Fresh banana leaves usually last 3–7 days at room temperature and up to 2–3 weeks if refrigerated. Dried or treated banana leaves can last much longer.

What are the benefits of banana stems?

Banana stems are rich in fiber, vitamins, and minerals; they aid digestion, support weight loss, help manage diabetes, and act as a natural detox for the body.

What is the spiritual meaning of the banana?

Spiritually, the banana symbolizes fertility, prosperity, and purity, and in many cultures it is offered in rituals to attract blessings and good fortune.

Can we keep banana plants at home according to Vastu?

Yes, according to Vastu, keeping a banana plant at home—especially in the northeast direction—is considered highly auspicious for prosperity, health, and spiritual growth.